3452 Part 2, Type II, which can be removed by water or solvents. It is used in non-destructive

testing for the detection of defects such as cracks, laps, cold shuts, porosity, bursts, casting

and welding discontinuities.

Ardrox® 907PB is a blend of biodegradable surfactants and high flash point distillates with a

low sulfur and halogen content.

Ardrox® 907PB is a low viscosity liquid penetrant. Its dark red color allows easy control and

monitoring of the washing process. The product offers the highest sensitivity level according

to ISO 3452-2.

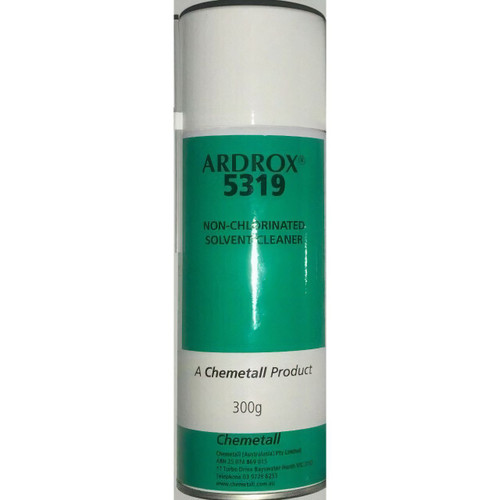

Ardrox® 907PB is available as bulk material and as aerosol cans. It is typically used together

with the Ardrox® range of cleaners and developers.

Method of use

Ardrox® 907PB may be applied by aerosol, brushing, flow-on, immersion, spray or by swab.

- Pre-Cleaning

Clean part with e.g. Ardrox® 9PR5, 9PR50 or 9PR88 before applying Ardrox® 907PB

penetrant. Apply cleaner to the part and wipe clean with cloth. The surface has to be free of

grease, oil and dirt. Allow part to dry before applying penetrant.

- Penetrant Application

Surface temperature should be between 10 and 50°C (50-120°F). Apply a thin even film of

Ardrox® 907PB penetrant to cover test area. Allow penetrant 10–30 minutes penetration time

before removing.

- Penetrant Removal

Remove excess surface penetrant with clean cloths, pre-moistened with cleaner (e.g.

Ardrox® 9PR5, 9PR50 or 9PR88). Alternatively, removal can be effected by gentle water

spray or by rinsing with waterDo not flush surface with cleaner as sensitivity will be impaired.

Repeat procedure until surface penetrant has been removed.

Thoroughly dry the component surface before developer application.

- Developer

Shake developer (e.g. Ardrox® NQ1 or 9D1B) thoroughly. Spray an even developer film over

the area to be inspected (spraying distance 30 cm / 1 ft.). Allow 10 – 30 minutes developing

time before evaluation. Inspection should take place in diffused white light of at least 500 lux

at the component surface.

- Inspection

Inspection should take place in diffused white light of at least 500 lux at the component

surface.

- Cleaning

After final inspection, components can be cleaned using e.g. Ardrox® 9PR5, 9PR50 or

9PR88.

Note: the procedure above is a recommendation only; where relevant, the process

specifications of the approving authorities must be followed.

Effects on material

When Ardrox® 907PB is used in the prescribed manner, no significant corrosion is likely to

occur on commonly used constructional metals. The product may stain or soften some

plastics and rubbers and, where appropriate, a compatibility test should be carried out.

Storage

Store in a cool place, protect from freezing conditions. Shelf life is 36 months.

Labor and environmentalprotection

Before operating the process described it is important that this complete document, together

with any relevant Safety Data sheets, be read and understood.

All local and national regulations on the transport, storage, use and waste treatment of

chemicals in concentrated or diluted form and as working solutions must be obeyed.

General Information

Chemetall supplies a wide range of chemical products and associated equipment for

cleaning, descaling, paint and carbon removal, metal working and protection and nondestructive testing. Sales Executives are available to advice on specific problems and

applications.

| Inner Qty: | 12 |

| Weight (Kgs): | 0.44 |

| In Stock: | Yes |