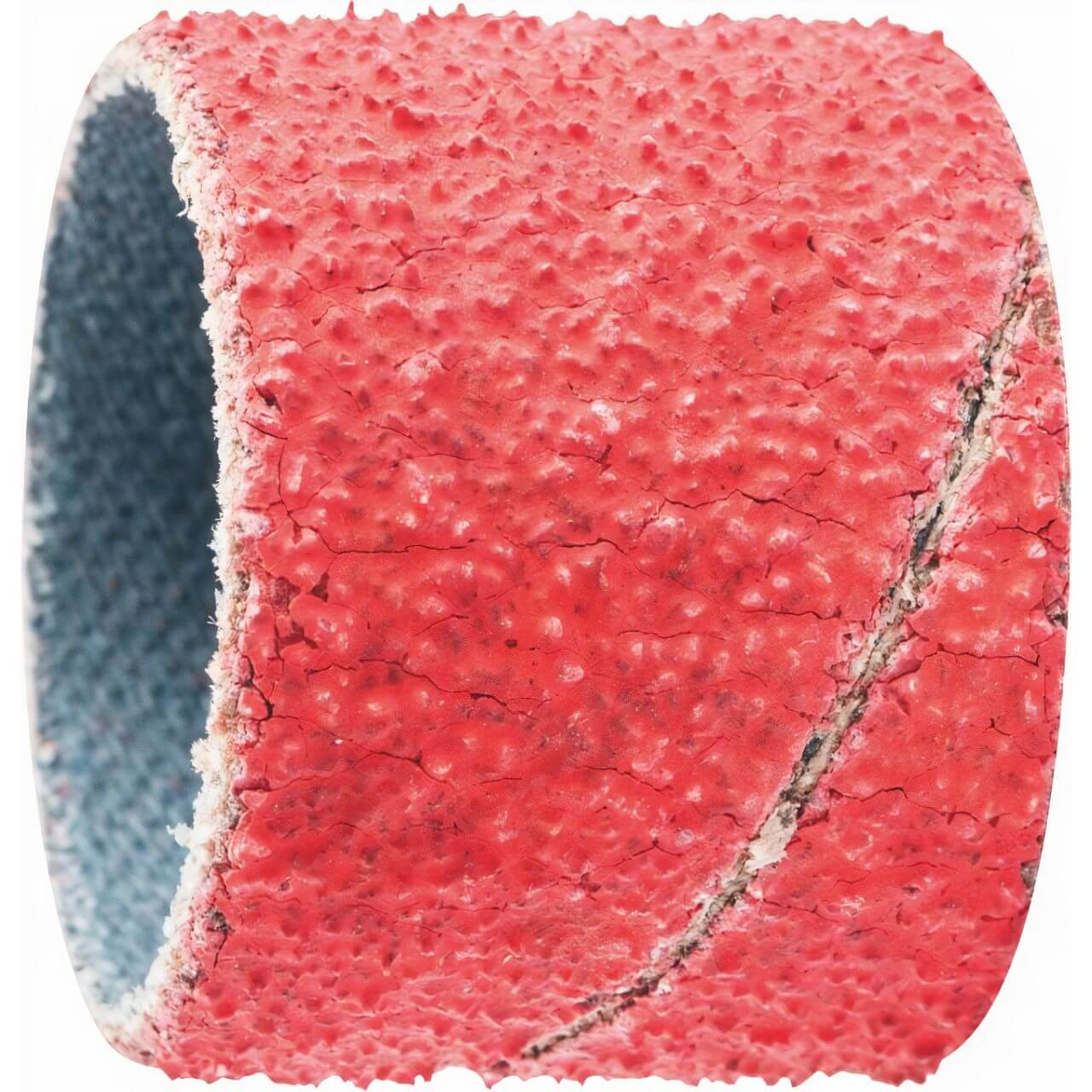

For aggressive grinding with maximum stock removal on hard and tough materials which do not conduct heat well. Active grinding additives in the coating significantly improve stock removal, prevent clogging and result in cooler grinding.

Abrasive: Ceramic oxide grain CO-COOL

Use matching, reusable rubber drum holder

Abrasive spiral bands are designated "Cylindrical Abrasive Sleeves" according to ISO 2421.

Advantages

- Because of slots, the holder expands during use, guaranteeing that the abrasive spiral band is firmly clamped in place

- Outstanding tool life due to special manufacturing process - even under the most demanding operating conditions

- Particularly high stock removal and high aggressiveness of the abrasive

Recommendations for use

- Abrasive spiral bands can be mounted and removed by turning them slightly to the right

- Abrasive spiral bands are easier to mount when the rubber drum holder is mounted on the tool drive

- The secure attachment of the abrasive spiral band is only guaranteed if the minimum rotational speed is observed

- Abrasive spiral bands achieve their best performance at a recommended cutting speed of 20-30 m/s

- Use grinding oil that is suitable for the material in order to significantly increase the tool life and the abrasive performance of the tools.

Application examples

- Removing weld seams in steel construction

- Fine grinding work in equipment, tank and vessel construction

- Post-processing for assembly and repair work

- Machining edges and contours in aircraft engine construction

Safety notes

- The maximum permitted peripheral speed is 30 m/s

- For safety reasons, it is imperative to remain within the stated maximum permitted rotational speed at all times

- Do not allow abrasive spiral bands to protrude beyond the rubber body

| Inner Qty: | 100 |

| Estimated Lead Time: | 3-5 days |