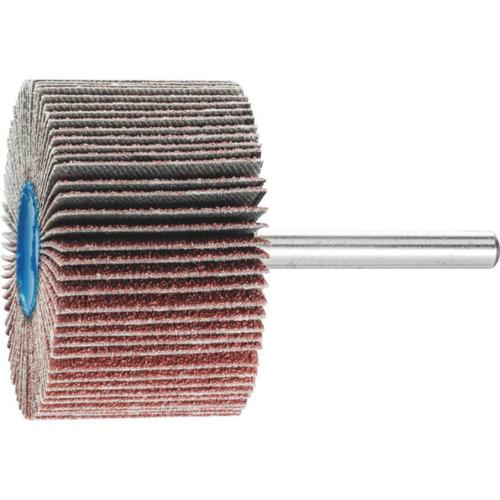

Advantages

- High flexibility

- High stock removal due to the aggressive coated abrasive

- Carrier material wears off uniformly and without residue on the workpiece surface, meaning that sharp abrasive grit is exposed at all times

- Due to the flat cast core construction, the face of the mounted flap wheels can be used to work very close to edges and in corners

Recommendations for use

- Mounted flap wheels achieve their best performance at a recommended cutting speed of 15-20 m/s. This provides an ideal compromise between stock removal, surface quality, thermal load on the workpiece and tool wear.

- Flexible shafts, electric and air-powered straight grinders can be used as tool drives

- Use grinding oil that is suitable for the material in order to significantly increase the tool life and the abrasive performance of the tools.

Safety notes

- For safety reasons, it is imperative to remain within the stated maximum permitted rotational speed at all times

- Safety is only guaranteed if:

- The clamping depth is at least 15 mm

- The specified maximum rotational speed for unsupported shank lengths is not exceeded

| Inner Qty: | 10 |

| Estimated Lead Time: | 3-5 days |

| Weight (Kgs): | 0.07 |

| In Stock: | No |