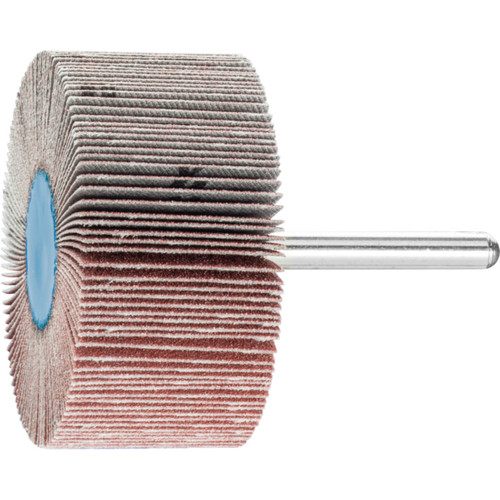

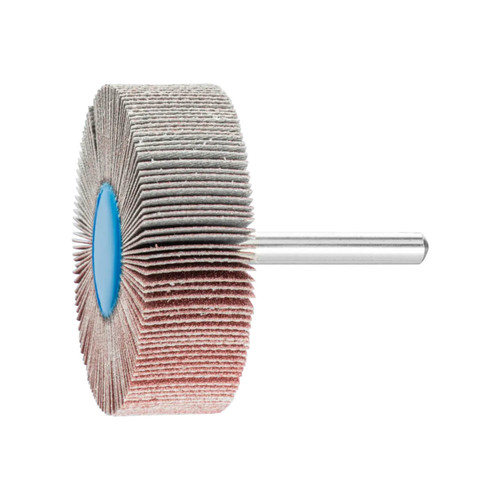

FEATURES:

- High flexibility

- High stock removal due to the aggressive coated abrasive

- Carrier material wears off uniformly and without residue on the workpiece surface, meaning that sharp abrasive grit is exposed at all times

- Due to the flat cast core construction, the face of the mounted flap wheels can be used to work very close to edges and in corners

RECOMMENDATIONS FOR USE:

- Mounted flap wheels achieve their best performance at a recommended cutting speed of 20 m/s. This provides an ideal compromise between stock removal, surface quality, thermal load on the workpiece and tool wear.

- Flexible shafts, electric and air-powered straight grinders can be used as tool drives

- Use grinding oil that is suitable for the material in order to significantly increase the tool life and the abrasive performance of the tools.

MATERIALS THAT CAN BE WORKED:

- Aluminium

- Copper

- Other non-ferrous metals

- Soft non-ferrous metal

- Brass

- Stainless steel (INOX)

- Grey/nodular cast iron (GG/GJL, GGG/GJS)

- Annealed cast iron

- Hardened, heat-treated steels over 1200 N/mm2 (over 38 HRC)

- Steel materials with a hardness over 54 HRC

- Steel, cast steel

- Steels up to 1200 N/mmŒ_ (<; 38 HRC)

- Cast steel

APPLICATIONS:

- Leveling

- Deburring

- Surface work

- Weld dressing

- Structuring (matt finishing, brush matting and satin finishing)

- Fine grinding in multiple steps

SPECIFICATIONS:

- Size mm:51 x 25

- Grit:40

| Estimated Lead Time: | 3-5 days |

| Inner Qty: | 10 |