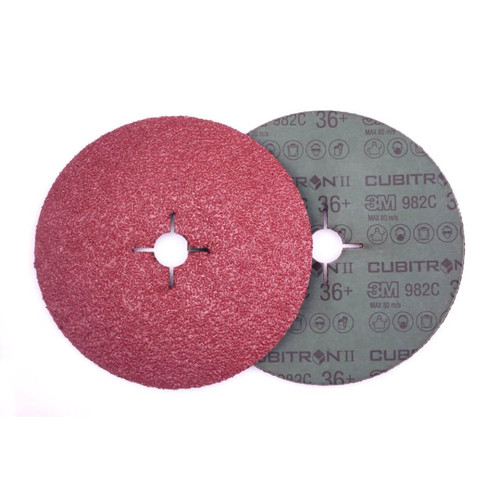

The 3M™ Cubitron™ II Fibre Disc 982C is well-suited for edge chamfering, beveling, and removing carbon steel welds, mill scale, pits and imperfections, machining grooves, and more.

Proprietary Cubitron™ II products have raised the bar for high-performing abrasives. 3M engineers started with 3M™ Ceramic Abrasive Grain and used 3M Precision Shaped Grain technology to generate triangular shaped grains that are electrostatically oriented on the backing to form sharp peaks and maximize cutting potential. These peaks act like individual cutting tools that slice through metal, and continuously shelf-sharpen as the points break off. The grains wear evenly and self-sharpen, reducing heat due to friction for up to twice the life of other fiber discs, with less grinding pressure. The result is that Cubitron™ II discs outcut and outlast every conventional ceramic industrial abrasive disc on the market, maximizing productivity and minimizing operator fatigue.

Fiber discs are heavy-duty discs ideal for weld removal, grinding, and blending large and small areas of metal surfaces. They feature a tough, stiff backing made from vulcanized fiber that resist wear and can handle tough grinding applications.

- 3M Precision Shaped Grain maintains super-sharp points that cut exceptionally fast with less pressure

- Disc life is significantly longer, completing more parts per disc and requiring fewer disc changes

- Triangular-shaped ceramic grain wears evenly, runs cool, and optimizes mineral breakdown

- Stiff fiber backing and a strong resin bond provide durability and tear-resistance for heavyweight applications such as high-pressure weld grinding,and can be used wet or dry

- 7/8" center hole mount is compatible with 3M™ Disc Pad Face Plates and Hubs, and requires the use of a disc retainer nut (all sold separately)

- Complete carbon steel solution

| Inner Qty: | 25 |

| Estimated Lead Time: | 5-8 days |

| Weight (Kgs): | 0.01 |